Manufacturing information system

Context relevant provision of information

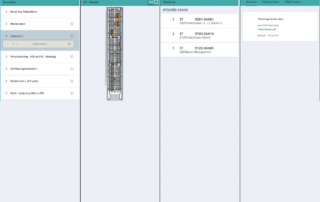

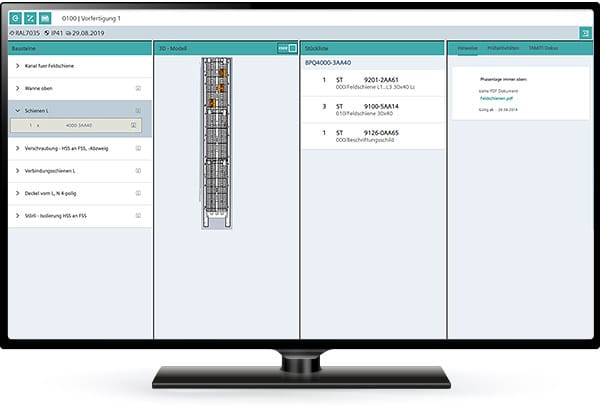

With this app, the information required for the manufacturing of the products of a large German company is made available to the respective workstations in a targeted manner. Every product manufactured there is a customer-specific solution. Previously, the required information was printed out and prepared manually before production started.

The Simplifier application makes it possible to eliminate the paper documents at workstations. From the multitude of information, the employee in the plant only sees what is relevant for the correct and quality-oriented execution of the current process step.

It is started by scanning a QR code on the product to be manufactured.

The application accelerates the preparation and execution of production significantly, increases quality and thus productivity.

Highlights of this application

Combines four independent data sources with each other

Hand scanner records QR code to start the app

Provision of relevant information at the workstation

LED display for mounting components in the right place

Use of data as it should be

In order to be able to manufacture the product in the right quality, the necessary information needs to be made available at the respective workstations.

To this end, four different independent data sources were combined with each other:

It is the combination of all data and the displaying of data relevant only to the respective order that makes the system so valuable for production. Unnecessary searching for the required data is now a thing of the past.