Optimal data utilization and efficiency in production through low-code applications

Leading electrical and power engineering manufacturer increases flexibility in line production, thereby increasing productivity while reducing costs and successfully implements the Connected Worker approach.

1. Initial situation and challenge

The manufacturing industry in particular has the opportunity to benefit from the enormous potential of digital transformation: increased productivity, reduced production costs, increased competitiveness and zero downtime. At the same time, the variety of data used from business systems and machines makes manual processes very time-consuming. Providing, capturing and processing data and ensuring availability are processes that generate additional work in addition to the actual activity. Therefore, digital applications are indispensable for successful process handling in this industry.

Our client a leading electrical and power engineering manufacturer had significant challenges in digitizing the production line within the division at one of its southern German sites. The focus in production is on customer-specific projects of low-voltage electric motors with batch size 1. These require a high manual production share, so that humans still play an important role in the result.

Customer information

The following challenges had to be solved in this factory:

Paper-based processes

Obtaining and passing on information involved a great deal of effort on the part of plant employees.

Decentralized data basis

Either there were too many different data sources or there were gaps in the data.

Stand-alone solutions

Made data transparency and quality more difficult and in some cases were not compatible with ERP systems, such as SAP.

Difficult data acquisition

Data was entered multiple times by employees and resulted in additional work.

Process breaks

Use of several tools for one process step, e.g. recording, rectification and billing of faults.

Necessary measures

Streamlining processes and increasing transparency were therefore essential. In the future, the workers were to interact seamlessly and just-in-time with data from different systems and machines. Manual processes were to be successively digitized. The aim was for the so-called Connected Worker to complete his work in a fraction of the time in the future, with documentation processes being simplified and without media breaks. This has the added advantage of reducing or even completely eliminating errors during data entry and transmission.

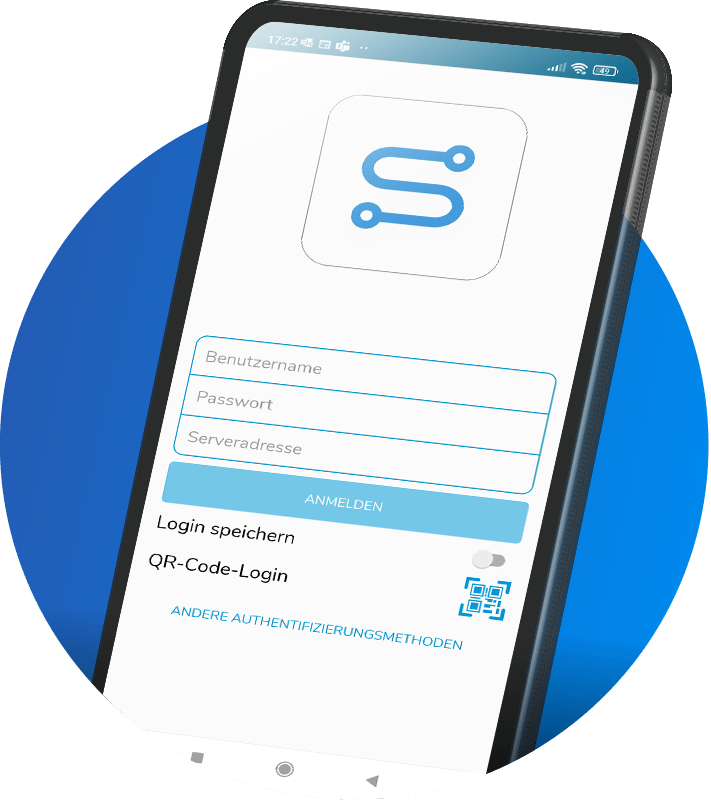

For the mobile solutions mentioned, flexible use of smart devices, be it a smartwatch, a smartphone or even a tablet, was an important prerequisite. Intuitive operation – as is known and proven in the private environment – was a decisive criterion for the acceptance of the applications among users.

“We have a heterogeneous world: We have to work with a lot of machine data and also integrate many different systems. There is a particularly intensive interface with the people themselves, i.e. they are at the center, have to control processes, work with data and be supported in the process. Of course, we had a huge need for digital and, above all, mobile solutions that would support each of the individual steps. But unfortunately, the sovereignty over the development of such solutions does not lie with us, which meant that we had to work without the necessary digital helpers for a long time.”

2. Solution

In search of an adequate solution and in order to reduce the dependency on implementation outside the specialist department, the customer came across the topic of the low-code development platform and Simplifier. The technology enabled new synergies to be identified. For the first time, it was possible to implement the very individual requirements in production with the existing heterogeneous landscape precisely and promptly, to make use of all the necessary data and to realize the whole thing with the company’s own resources.

The possibility of building the required IT software themselves and not having it end up in a demand ticket or having to request it from third parties was very appealing to the customer. “With Simplifier, we were able to take things into our own hands and control which applications, functions and front-ends we build ourselves. We can implement applications that are also modular, that are small, and still meet exactly the needs we have in the workshops, logistics, but also in the office areas,” said the plant manager of the Motion Control division enthusiastically.

This reduced much of the dependency on IT, and solutions were deployed much more quickly at the individual stations. Thanks to low-code technology, employees who brought expertise from the manufacturing floor could be deployed. With Simplifier, they were empowered to build, test and maintain the applications independently. Uniform usability and user experience, as well as the use of all the smart devices deployed, also achieved significantly greater acceptance among users – the connected workers.

Other advantages were that the self-explanatory use of the new applications made the training process much easier and reduced employee training to almost zero.

“With Simplifier, we finally have the huge opportunity to stop thinking in terms of monolithic systems and instead think in terms of modular applications – in order to redesign our architecture in this way. This means we can act faster, more agile and, above all, leaner. We are experiencing a culture change among our colleagues, who are hooked on quickly launching new applications, testing them with others, incorporating the feedback directly into the app, and going live within a short period of time.”

3. Results

With Simplifier’s agile development environment, the customer was able to put the first applications into production within a few weeks. Five employees familiarized themselves with the platform within a few days, created the connection to all relevant systems and thus the basis for being able to implement future applications within the plant in a short time.

With Simplifier’s support, the first functional application was implemented within 24 hours and made available live in the first iteration. This allowed important user feedback to be collected in order to further develop the app in just a few steps in such a way that it sustainably increased productivity in a crucial process step. The development phase was carried out directly in the specialist department without IT involvement, the employees of the respective stations were included in the tests, and the feedback was incorporated directly, without long coordination loops and complicated specifications.

The resulting application for incident management ensured that incidents were handled efficiently, evaluated and reduced enormously in the long term. Since the manual entry of incidents into the connected SAP ERP system was completely eliminated by the new app, they could be processed conveniently. This offered the plant employees enormous added value.

The customer was able to take 8 apps live within the plant in the first 6 months and increase productivity by 25 percent, which increased the outcome of production by almost 15 percent in one year, or the number of units of electric motors produced each month from 13 to 14.

If we look at the ROI of using Simplifier to create the first 10 applications, according to the customer, we can already assume an ROI of less than 12 months. On the one hand, this is due to the risk minimization in the creation process, in which applications with modular architecture are used instead of complex solutions. On the other hand, there is a high degree of flexibility due to the reusability of the application components and connectors, which can easily be used in other applications. Processes within an app template can be exchanged or adapted to requirements at any time. This plays a decisive role in the analysis of effort and costs, as there is great potential for savings here compared to the conventional creation process. Savings here averaged 50 percent. Overall, the cost structure is much leaner due to the use of in-house developers and on-board resources, so that, according to the customer, the applications can be implemented much more cost-effectively. Paralyzing project management and additional commercial processes are eliminated or drastically reduced. The agile doer mentality thus leads to greater efficiency and more productivity in IT.

4. Outlook

In the next step, Simplifier is to become the standard tool for 10 more employees who have been using Excel macros or costly and time-consuming IT systems to generate applications.

In this way, the plant and the entire production line will be supplied with many small, multi-value, mobile applications. Within the entire division, independence and digitization will be driven in this way and the Connected Worker work model will be established.

The goal is to gradually replace the existing legacy solutions, such as those based on Excel Macro, Lotus Notes and Access, and to make them available via new technologies in order to ultimately be able to further increase the productivity of the plant.