WEINIG App Suite

Digitization in the woodworking machine sector

1. Initial situation

Even in industries with a long tradition such as the woodworking trade, mega trends like digitization and automation do not go unnoticed. At the same time, digital services offer mechanical engineering companies in particular the opportunity to maintain close contact with customers even after the sale.

The WEINIG Group is a manufacturer of woodworking machines. Its portfolio covers the complete process chain from sawmills to end products such as windows and profile strips. In 2015, WEINIG released the first version of the App Suite. It offers end customers free functions such as general information on existing machinery, calculation tools such as angle and planing step calculators as well as an additional channel for support requests to the WEINIG Service. In addition, monitoring functions can be booked for a monthly fee. These make the current and historical machine status or the progress of production orders more transparent. This app was developed by an external service provider in 2015. It has been adapted and expanded regularly in recent years.

„We were looking for a technology that would allow us to continuously develop our App Suite based on our customers’ needs and to follow a clear software architecture. This was supposed to make it possible for new applications and optimizations to be implemented in a quick yet structured manner by different developers.“

Jochen Ganz, Head of New Business & Innovation, WEINIG Group

2. Challenge

Since the app had been created in a proprietary way, it had been very difficult to integrate the desired new functions. Any changes were always time-consuming and costly. In the future, WEINIG does not want to have to call on the service provider for every change request. Rather, WEINIG wanted to be able to add as many new functions as possible and implement adjustments quickly and easily.

What´s more, the app had to be designed more modularly, which made role and rights management necessary. The required interfaces – for example to Salesforce – were supposed to be easy to integrate.

Low-code was supposed to put WEINIG in the position to create the required solutions largely autonomously. Any advantages that low-code platforms bring with them were supposed to be used for the further development of the app.

3. Solution

On the part of Simplifier, the app was rebuilt in its essential functions. In the course of this the user interface was modernized and the navigation was made much clearer. Another advantage of the new App Suite is the simplified user administration. This makes it possible to offer a demo version and to assign individual app functions individually to each app account. The assignment between the app account and the customer and machine inventory data is done via Salesforce.

A WEINIG software architect was involved in the process and trained in the essential simplifier features. Thus, he is now able to implement the applications required by WEINIG himself. In this way, the growing customer requirements can be met even better.

“With Simplifier, we can not only create apps quickly by configuring and clicking together, but also intervene directly in the source code at any time to implement more complex features.”

Christoph Ruckstetter, Software architect, WEINIG Tauberbischofsheim

WEINIG App Suite

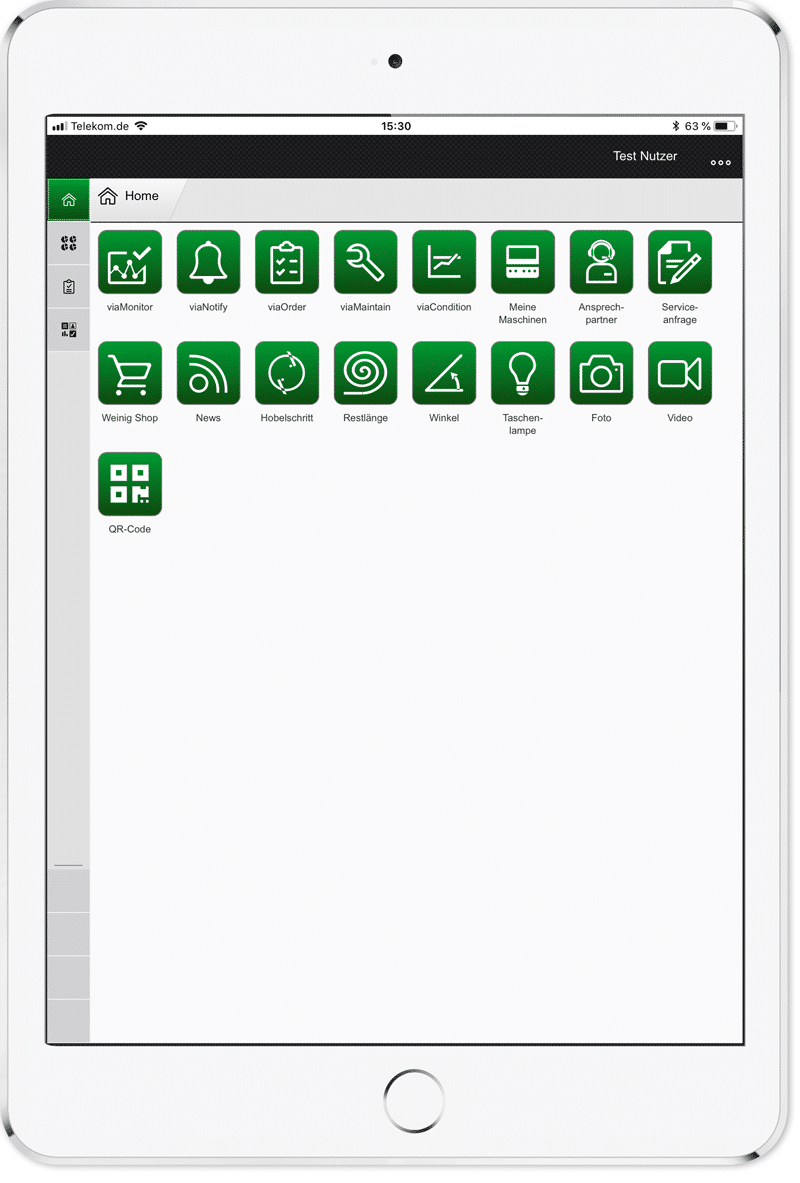

The viaFunctions of the WEINIG App Suite make it possible to keep track of the production of your own machines – worldwide and in real time:

Moreover, the app offers a customer-oriented service area. You can quickly and easily contact a WEINIG expert by e-mail or telephone or send messages directly from the app. In addition, there is an overview of the respective WEINIG machine park for each customer, including the appropriate contact persons.

In addition, the App Suite has helpful calculation functions such as angle calculator, planing step calculator or a residual length calculator for edge banding.

4. Results

WEINIG has a future-proof technological advantage thanks to the low-code platform Simplifier. Thus, WEINIG can save both time and money, since the required applications can be developed much faster due to the prefabricated elements of Simplifier and no more highly paid external service providers are required. In addition, quality is maintained through tested programming codes.

This allows the mechanical engineering specialist to set itself apart from the competition by being able to add new functions to its app as quickly as possible and independently. WEINIG was able to present this approach at Ligna 2019 (the world’s leading trade fair for woodworking and wood processing) in Hanover.

The WEINIG App Suite is available as a stand-alone app for iOS and Android, and as a browser application at www.weinig.app

5. Outlook

Through continuous further developments in the WEINIG App Suite, WEINIG would like to make everyday work in the woodworking industry easier in the future and thus also be an even stronger partner for the customer after the sale of the machines. In addition, the low-code platform Simplifier is also used internally to optimize process flows, which is no problem thanks to the role and rights management already implemented.

It is also possible to continuously add new functions that make the daily work of customers easier.